WHAT IS MICROSILICA?

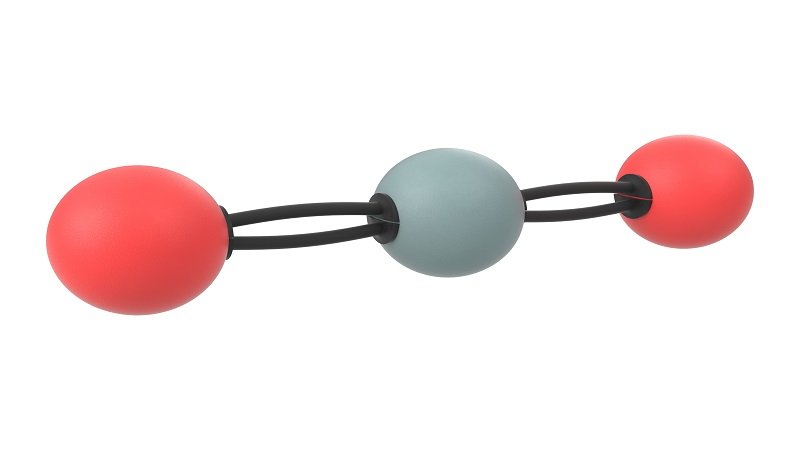

Microsilica (silica fume) is a byproduct from silicon metal or ferrosilicon industries,is an amorphous silicon dioxide – SiO2 which is generated as a gas in submerged electrical arc furnaces during the reduction of extreme pure quartz. As the molten metal is produced, a silica-based gas is emitted. This gaseous fume, as it rises, cools rapidly and forms extremely minute,Amorphous, spherical particles. The microsilica is collected in a bag house, a system for filtering the hot air and gases vented from the furnace. This gas vapor is condensed in bag house collectors as very fine powder of spherical particles that average 0.1 to 0.3 microns in diameter with a surface area of 17 to 30 m2/g.